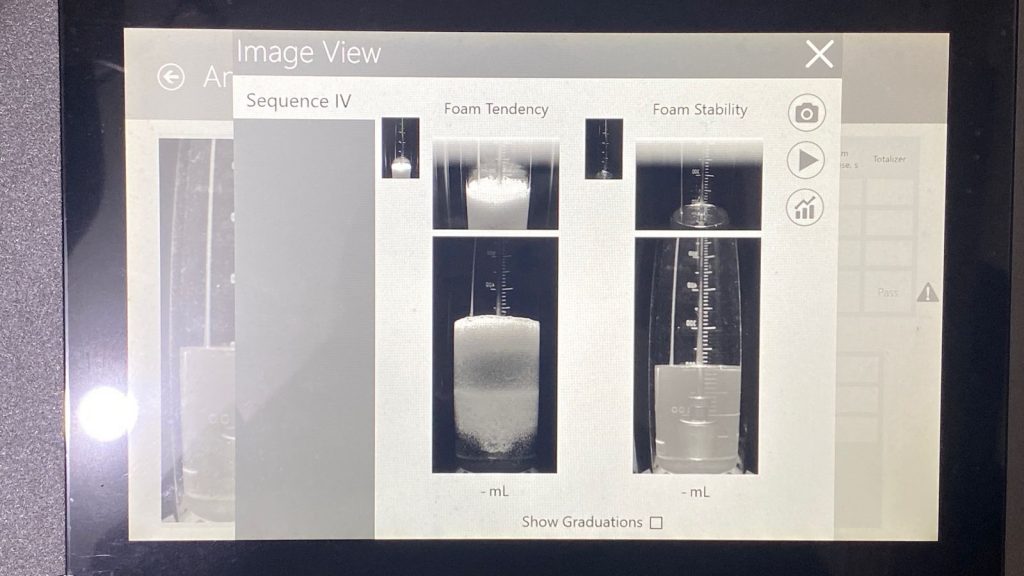

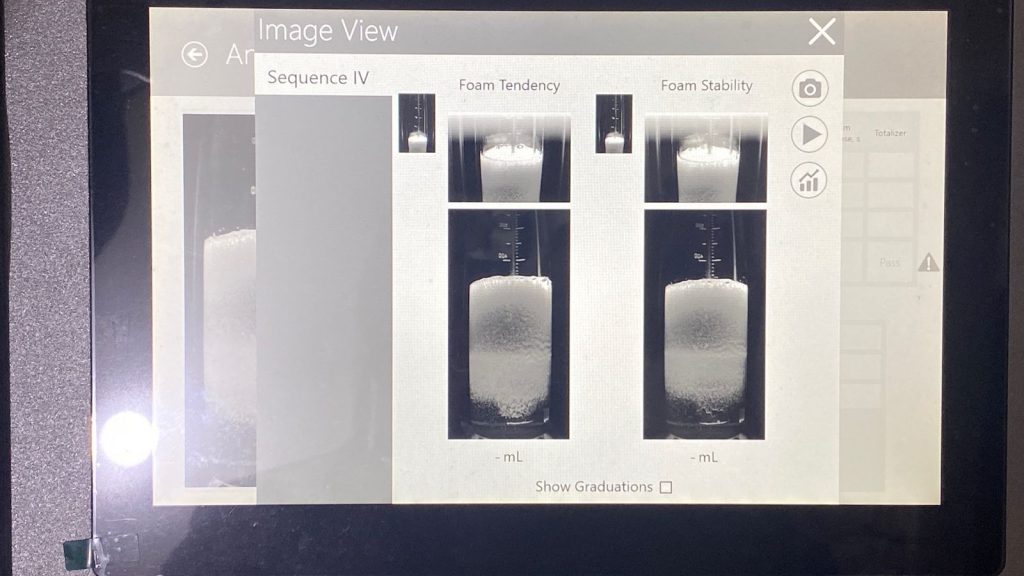

TheFoam Digital Detection Imaging (FoamDDI) foam stability tester accurately controls airflow, temperature, and sequencing when testing foam tendencies in oils and lubricants. The fully automatic FoamDDI augments these measurements using our unique VISION Algorithm to accurately determine both the station and dynamic foam heights with precision and accuracy. Relying on the human eye to measure foam heights is unreliable, time consuming and can be costly due to user bias. The FoamDDI foam tester eliminates these issues and the need for sample manipulation and critical timing involved with other foam detector methods. Using a patented heating and cooling system the FoamDDI records, calculates, and displays accurate results with little to no operation bias. Determinations come from this foam stability tester in minutes

Methode ASTM, D892, D6082, BS 2000, Part 156, FTM, 791-3211, IP, 146, ISO, 6247

Unique automated vision detection system for analyzing foam characteristics.

– Accurate measurement of foam characteristics with high precision cameras.

– Real-time monitoring and recording.

– User-friendly design with easy setup.

– Durable and low-maintenance equipment.

– Compliant with industry standards.

Intallation On Site